Is It Necessary to Calibrate CT PT Transformers Regularly?

Introduction

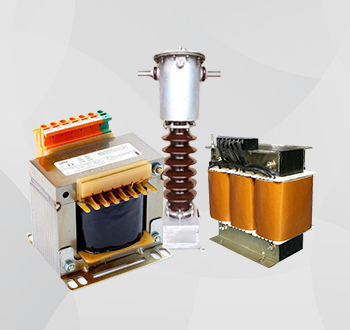

Current Transformers (CT) and Potential Transformers (PT) are critical components of power systems, used for measurement, monitoring, and protection. Their accuracy directly impacts the performance and safety of electrical networks. Therefore, the question arises: Is it necessary to calibrate CT PT transformers regularly? This blog dives deep into the importance of regular calibration, its impact on system reliability, and the best practices involved.

What Are CT and PT Transformers?

Current Transformers (CTs) are devices that reduce high currents to manageable values for measurement or protection devices. They provide isolated, scaled-down current signals proportional to the primary current flowing through the conductor.

Potential Transformers (PTs), also known as voltage transformers, step down high voltages to lower, standardized voltages for metering and protective relays. Both types are indispensable in power distribution, energy metering, and protection schemes.

Why Calibration of CT PT Transformers Matters

Calibration is the process of verifying and adjusting the accuracy of CT and PT transformers. Over time, factors such as aging, environmental conditions, mechanical stresses, and electrical disturbances can affect their performance. Regular calibration ensures:

- Accuracy: Measurement devices receive precise data, crucial for billing and system monitoring.

- Protection: Protective relays rely on accurate signals from CT/PTs to detect faults and isolate faulty sections.

- Compliance: Calibration maintains adherence to industry standards and regulatory requirements.

- Reliability: Regular checks prevent unexpected failures and reduce downtime.

- Safety: Incorrect readings can lead to unsafe operating conditions.

Without calibration, transformers may produce erroneous signals, leading to misoperation of protective devices or inaccurate metering, which can be costly and dangerous.

When Should CT PT Transformers Be Calibrated?

The frequency of calibration depends on several factors:

- Manufacturer Recommendations: Typically, manufacturers suggest calibration intervals.

- Usage Conditions: Harsh environments with temperature fluctuations, humidity, or pollution may require more frequent calibration.

- Criticality of Application: Transformers used in critical systems like power plants may require stricter schedules.

- Historical Data: Past calibration results can help determine optimal intervals.

In general, an annual or bi-annual calibration cycle is common practice for most CT/PT transformers.

How Is Calibration Performed?

Calibration involves comparing the output of the CT/PT transformer to a known standard or reference device under controlled conditions. The steps typically include:

- Visual Inspection: Checking for physical damage, corrosion, or loose connections.

- Electrical Testing: Applying test currents or voltages and measuring output signals.

- Accuracy Verification: Comparing measurements with certified standards to determine errors.

- Adjustment: If deviations exceed permissible limits, adjustments or repairs are made.

- Documentation: Calibration certificates and reports are generated for compliance and record-keeping.

Modern calibration equipment offers automated and precise testing, reducing human error.

Benefits of Regular Calibration

- Prevents Financial Losses: Ensures accurate energy billing and prevents revenue loss.

- Improves System Protection: Avoids malfunctions and reduces fault clearing times.

- Extends Transformer Life: Early detection of problems prevents permanent damage.

- Regulatory Compliance: Meets national and international standards like IEC and ANSI.

- Enhanced Safety: Minimizes risk to personnel and equipment.

Risks of Neglecting Calibration

Ignoring regular calibration can lead to:

- Faulty relay operation causing blackouts or equipment damage.

- Incorrect energy measurements leading to disputes or losses.

- Increased downtime due to undetected transformer failures.

- Safety hazards from undetected electrical faults.

About LES Ecotonik Systems

LES Ecotonik Systems is a leader in manufacturing precision CT and PT transformers, specializing in high-quality calibration services and customized transformer solutions. With decades of experience and ISO certification, LES focuses on innovation, accuracy, and compliance with global standards.

LES offers comprehensive after-sales support, including routine calibration, maintenance, and troubleshooting services to ensure long-term reliability of your transformers. Their expert engineers and state-of-the-art testing labs help industries maintain optimal power system performance.

Conclusion

In conclusion, regular calibration of CT PT transformers is not just necessary but essential for maintaining accuracy, safety, and efficiency in electrical power systems. Proper calibration prevents costly errors, protects critical infrastructure, and ensures compliance with industry standards.

When seeking reliable CT and PT transformers or calibration services, consider partnering with a reputed CT PT Transformer Manufacturer in Hyderabad. Such manufacturers provide high-quality products combined with professional calibration and maintenance services, safeguarding your investments and operations.